3D print bed leveling: Sounds boring, right? Wrong! It’s the unsung hero of successful 3D printing, the secret sauce to transforming wobbly blobs of plastic into magnificent, layer-perfect creations. Get it wrong, and you’ll be staring at a warped, sad excuse for a print. Get it right, and you’ll be the envy of every maker in your neighborhood.

This guide will take you from paper-shim-wielding novice to bed-leveling ninja, covering everything from manual adjustments to the glorious automation of advanced systems.

We’ll delve into the nitty-gritty of different leveling methods, troubleshoot those pesky adhesion issues, and even explore the mystical arts of mesh bed leveling. Whether you’re wrestling with a Cartesian printer or a finicky Delta, we’ve got the tips and tricks to get your print bed perfectly level, ensuring your 3D printing dreams become reality (without the frustration!).

3D Print Bed Leveling: A Level-Headed Guide

Ah, the joys of 3D printing! Creating intricate masterpieces from the digital realm, layer by painstaking layer. But before you unleash your inner digital sculptor, there’s one crucial step that often gets overlooked: bed leveling. Think of it as the foundation of your 3D printed castle – without a solid base, your creation will crumble. This comprehensive guide will take you through the ins and outs of bed leveling, transforming you from a leveling novice to a master of the perfectly flat print surface.

Introduction to 3D Print Bed Leveling

Proper bed leveling is paramount for successful 3D printing. It ensures that the first layer of your print adheres perfectly to the bed, preventing warping, adhesion issues, and ultimately, failed prints. An improperly leveled bed results in inconsistent layer height, leading to a wobbly, misshapen, and ultimately unusable print. Several methods exist for achieving a level bed, ranging from manual adjustments to sophisticated automated systems.

Manual Bed Leveling Techniques

Manual bed leveling, while requiring a bit more patience, offers a great way to understand the fundamentals of print bed alignment. The most common method involves using a piece of paper. By adjusting the bed screws, you create a consistent gap between the nozzle and the bed, ensuring even adhesion.

- Begin by heating the nozzle to the printing temperature.

- Carefully slide a piece of paper between the nozzle and the bed at several points across the bed.

- Adjust the bed screws until the paper slides smoothly with a slight resistance across the entire bed surface.

- Repeat this process until you achieve a consistent, snug fit.

Remember, a little resistance is your friend; you want a tight enough fit to ensure good adhesion but not so tight that the paper is stuck.

| Method | Advantages | Disadvantages |

|---|---|---|

| Manual Bed Leveling | Cost-effective, provides a good understanding of bed mechanics | Time-consuming, requires precision and patience, may not be perfectly level |

Automated Bed Leveling Systems, 3d print bed leveling

Automated Bed Leveling (ABL) systems take the guesswork out of bed leveling. These systems use sensors to automatically measure the distance between the nozzle and the bed, adjusting the bed accordingly. Different ABL systems utilize various sensors, each with its own strengths and weaknesses.

- Inductive Sensors: Measure the distance using electromagnetic fields.

- Capacitive Sensors: Measure the distance based on changes in capacitance.

The calibration process varies depending on the specific ABL system, but generally involves the system probing multiple points on the bed and creating a level map.

A flowchart for an automated bed leveling process would start with the system powering up, followed by sensor initialization. Next, the system would probe multiple points on the bed and create a height map. Based on this map, the system would then adjust the bed screws to achieve optimal leveling, concluding with a confirmation that the bed is level.

Troubleshooting Common Bed Leveling Issues

Even with careful leveling, issues can arise. Uneven bed adhesion, warping, and lifting are common problems, often stemming from improper leveling or other factors.

- Problem: Uneven bed adhesion. Solution: Recheck bed leveling, clean the bed thoroughly, adjust nozzle temperature.

- Problem: Warping. Solution: Reduce print speed, use a heated bed, add a brim or raft.

- Problem: Lifting. Solution: Ensure proper bed adhesion, reduce print speed, increase bed temperature.

Analyzing print defects, such as a consistently higher or lower first layer on one side of the print, can pinpoint the location of leveling problems.

Bed Leveling for Different Printer Types

Bed leveling procedures vary slightly depending on the printer type (Cartesian, Delta, Prusa i3) and bed material (glass, PEI). Each type presents unique challenges and considerations.

| Printer Type | Leveling Method | Challenges | Considerations |

|---|---|---|---|

| Cartesian | Manual or Automated | Adjusting multiple screws | Bed material expansion |

| Delta | Usually Automated | More complex geometry | Calibration is crucial |

| Prusa i3 | Manual or Automated | Simple to adjust | Consistent bed adhesion |

Advanced Bed Leveling Techniques

Mesh bed leveling takes bed leveling to the next level (pun intended!). This technique creates a 3D map of the bed’s surface, compensating for any imperfections and ensuring perfect adhesion across the entire print area. Software tools facilitate this process, guiding you through the creation and application of the mesh level map.

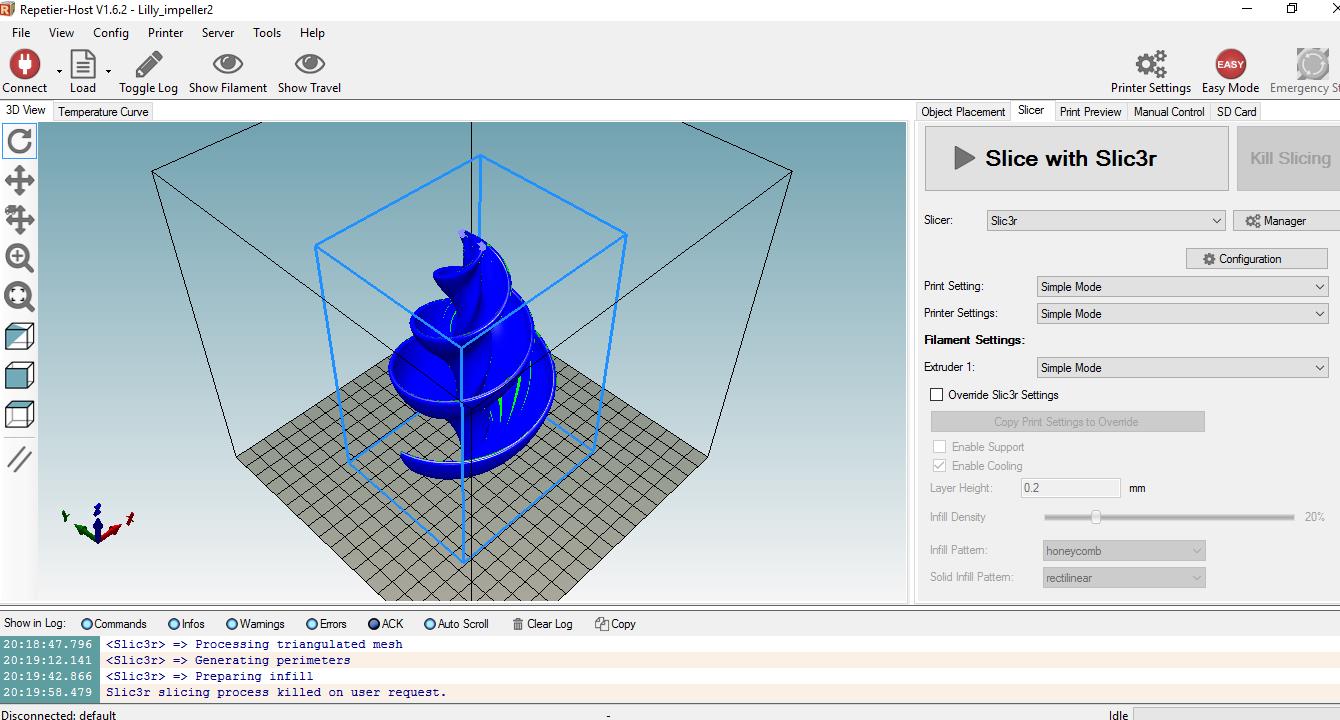

Generating a mesh bed level map involves probing numerous points across the bed surface, creating a matrix of height values. This data is then used by the slicer software to compensate for bed imperfections, ensuring even layer heights throughout the print.

Maintaining a Level Print Bed

Regular maintenance is key to preserving a level print bed. This involves cleaning the bed surface to remove any residue, ensuring proper storage to prevent misalignment, and occasionally re-leveling the bed as needed.

A visual representation of proper print bed maintenance would show a step-by-step process: first, cleaning the bed with isopropyl alcohol and a lint-free cloth; second, inspecting the bed screws for tightness; third, performing a test print to verify leveling; and finally, storing the printer in a clean, dry environment.

When investigating detailed guidance, check out minimalist skincare routine now.

So, there you have it – a journey through the often-overlooked, yet critically important world of 3D print bed leveling. From the simple elegance of manual adjustments to the futuristic precision of automated systems, we’ve covered the gamut. Remember, a level bed is the foundation of a successful print. Master this skill, and you’ll unlock a new level of 3D printing prowess, creating prints so smooth, so perfect, they’ll make your printer blush.

Now go forth and conquer those leveling challenges! Your perfectly-printed future awaits!

FAQ Section

What happens if my bed isn’t level?

An uneven bed leads to inconsistent layer adhesion, resulting in warping, lifting, and ultimately, a failed print. Think wobbly towers and sad little blobs.

How often should I level my bed?

It depends on your printer and how often you use it. Regular checks (before each print is ideal), and re-leveling as needed, are recommended. Changes in temperature and general wear and tear can affect bed level.

My prints are sticking too much to the bed; what’s wrong?

This is often due to an excessively level bed (too close to the nozzle). Try adjusting your z-offset or slightly raising the bed. Also, check your bed adhesion solution.

Can I level my bed without removing the print bed?

It depends on your printer. Some printers allow for leveling adjustments without removing the bed, while others require removal for access to the adjustment screws.

What’s the difference between manual and automated bed leveling?

Manual leveling involves manually adjusting screws to level the bed using a piece of paper. Automated bed leveling (ABL) uses sensors to automatically measure and adjust the bed’s level.