Metal 3D printing at home? Sounds like something out of a sci-fi movie, right? Forget clunky, expensive industrial machines – the future of metal fabrication is now surprisingly accessible (and maybe a little bit messy). This guide dives into the fascinating world of crafting metal masterpieces in your own garage, exploring the technologies, materials, safety precautions, and even the slightly dodgy legal bits.

Buckle up, it’s going to be a wild ride!

From choosing the right printer (binder jetting? Direct metal laser sintering? Don’t worry, we’ll explain the differences!), to sourcing metal powders (safely, of course!), we’ll cover everything you need to know to transform your spare room into a miniature metal foundry. We’ll also tackle the design process, troubleshooting common problems, and even the ethical considerations of creating tiny metal dragons in your basement.

So, are you ready to unleash your inner metal-smith?

Home Metal 3D Printing: A Wild Ride into the Future (From Your Garage!): Metal 3d Printing At Home

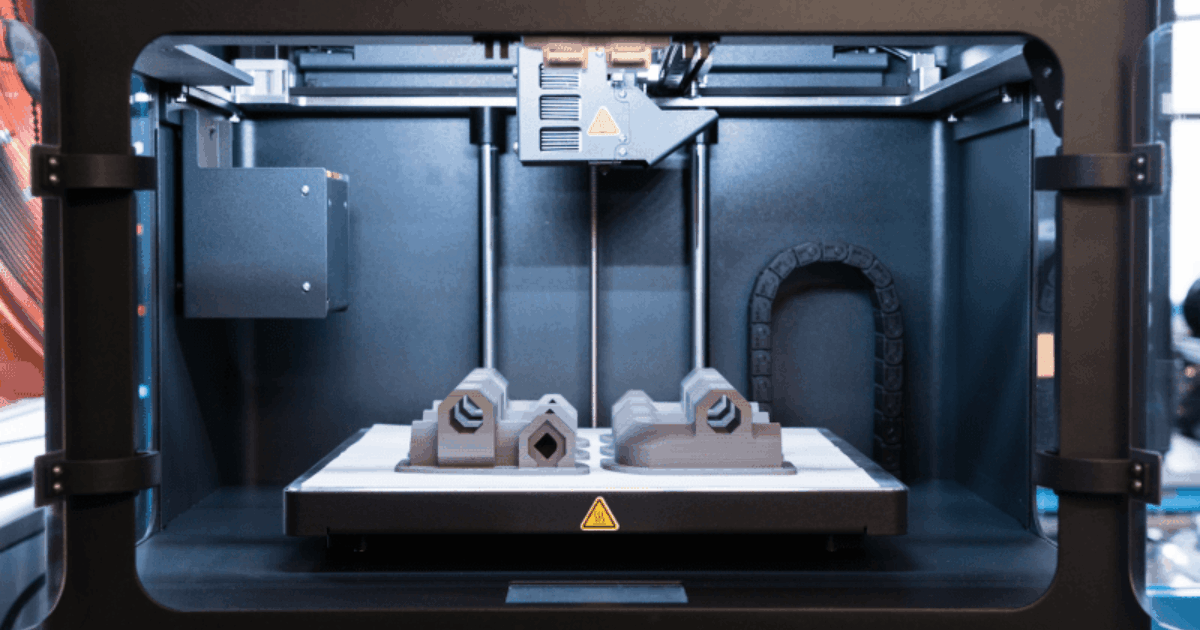

Forget clunky, expensive industrial machines – the world of metal 3D printing is shrinking, and it’s about to land squarely in your garage (with appropriate safety precautions, of course!). This guide dives headfirst into the exciting, slightly terrifying, and undeniably cool world of home metal 3D printing. We’ll cover everything from choosing the right technology to navigating the legal minefield (because, let’s face it, melting metal at home raises a few eyebrows).

Home Metal 3D Printing Technologies

Several technologies are vying for a spot in your home workshop. Each boasts unique strengths and weaknesses, and the “best” choice depends heavily on your budget, technical skills, and desired level of metal-melting mayhem.

While full-scale industrial processes like Electron Beam Melting (EBM) and Selective Laser Melting (SLM) are out of the question for most home users due to their size, cost, and safety requirements, some more accessible options exist. Binder Jetting, for example, offers a relatively gentler introduction to the world of metal 3D printing, though the resulting parts may require further processing.

Cost-effectiveness is a major factor. Binder jetting systems generally sit at the lower end of the price spectrum, while even smaller-scale Direct Metal Laser Sintering (DMLS) systems can still represent a significant investment. Remember to factor in the cost of metal powders, which can be substantial.

Safety is paramount. Metal powders are often fine, and can be easily inhaled or ignite. Always operate in a well-ventilated area with appropriate respiratory protection, and follow all manufacturer’s safety guidelines religiously. Improper handling can lead to serious health consequences, or worse, a fiery explosion that will definitely impress your neighbors (in a bad way).

| Technology | Pros | Cons | Cost |

|---|---|---|---|

| Binder Jetting | Relatively low cost, less demanding safety requirements | Lower resolution, parts often require further processing | $ (Lower end) |

Direct Metal Laser Sintering (DMLS)

|

Higher resolution, stronger parts | High initial cost, complex operation, stringent safety requirements | $$$ (Mid to High end) |

Electron Beam Melting (EBM)

|

Very high resolution, excellent material properties | Extremely high cost, requires vacuum chamber, extreme safety precautions | $$$$$ (Prohibitively expensive for home use) |

Materials and Supplies for Home Metal 3D Printing

The heart of metal 3D printing lies in the metal powders. Common choices include stainless steel, titanium alloys (if you’re feeling adventurous), and aluminum alloys. Each offers different properties – strength, corrosion resistance, etc. – impacting the final product’s suitability for specific applications.

Do not overlook the opportunity to discover more about the subject of double cleansing with oil.

Sourcing these powders requires careful attention. Reputable suppliers are essential, as powder quality directly impacts print quality and safety. Storage is equally crucial; metal powders need to be kept dry and free from contamination. Think airtight containers in a controlled environment to prevent oxidation or accidental ignition. Regulatory compliance, especially concerning hazardous materials, must be strictly adhered to.

Local regulations may vary, so research is vital.

Support structures are frequently necessary during printing to prevent sagging or deformation. These are often made of sacrificial materials that are removed post-processing. Post-processing itself can involve heat treatment, machining, or other finishing steps to enhance the final part’s properties and aesthetics.

- Acquire metal powders from reputable suppliers.

- Store powders in airtight, labeled containers in a dry environment.

- Source appropriate support materials (often wax or resin).

- Research and acquire necessary post-processing tools and equipment (e.g., furnace, cleaning solutions).

- Understand and comply with all relevant safety and regulatory requirements.

Setting up a Home Metal 3D Printing Workspace

Your workspace needs to be more than just a corner of your garage. It demands respect and planning. Think of it as a miniature, high-tech forge, not a casual crafting area. Excellent ventilation is non-negotiable to remove potentially harmful fumes and fine metal particles. A dedicated dust collection system is a wise investment, and safety equipment, such as respirators, eye protection, and fire extinguishers, are absolute must-haves.

Setting up your workspace involves a methodical approach: secure a well-ventilated area, install a dust collection system, arrange your equipment for efficient workflow, and ensure all safety equipment is readily accessible. Think about fire safety and have a clear escape route.

Proper ventilation prevents the accumulation of hazardous fumes and particles, safeguarding your health. A dedicated dust collection system is crucial for capturing fine metal particles, preventing inhalation and maintaining a clean workspace. A poorly ventilated space with inadequate dust collection is a recipe for disaster.

Imagine a workspace: a well-lit area with a dedicated metal 3D printer, positioned away from flammable materials. Nearby is a dedicated dust collection system, efficiently sucking away any airborne particles. A well-organized shelving unit holds metal powders in sealed containers, alongside support materials and post-processing tools. Safety equipment, including a respirator, safety glasses, and a fire extinguisher, are readily accessible and clearly visible.

Designing and Preparing Files for Home Metal 3D Printing

Software is your digital forge. Popular choices include CAD software (like Fusion 360 or SolidWorks) for designing your parts, and slicing software (like Cura or PrusaSlicer) to prepare the print files. File formats typically used are STL (Stereolithography) or OBJ (Wavefront OBJ). Optimization is crucial; poorly designed files can lead to failed prints or inferior parts.

File optimization involves ensuring your design is structurally sound, taking into account the limitations of your specific metal 3D printing technology and the properties of the metal powder. Slicing parameters, such as layer height, infill density, and support structure generation, significantly impact print quality, build time, and material usage. Proper slicing ensures your printer understands the instructions and creates a successful print.

Designing parts for metal 3D printing requires careful consideration of material properties. Think about the final part’s intended use, required strength, and the metal’s behavior under stress. Remember, not every design is suitable for metal 3D printing. Complex geometries, thin walls, and intricate details might require extra support or may not be feasible with your specific setup.

Troubleshooting and Maintenance of Home Metal 3D Printers, Metal 3d printing at home

Even the most well-maintained printer will encounter hiccups. Common issues include clogged nozzles, inconsistent layer adhesion, or powder bridging. Solutions range from simple cleaning procedures to more complex adjustments of printer settings. Regular maintenance is key to preventing these issues.

A routine maintenance schedule should include regular cleaning of the print bed, nozzle, and other components, as well as checking for loose connections or worn parts. Calibration is essential to ensure accurate printing and prevent failures. Proper maintenance ensures the longevity and optimal performance of your printer.

- Clogged Nozzles: Clean with a suitable cleaning tool and compressed air.

- Inconsistent Layer Adhesion: Check build plate leveling and adjust printer settings.

- Powder Bridging: Adjust support structures and slicing parameters.

- Failed Prints: Review your file preparation, slicing settings, and printer calibration.

Legal and Ethical Considerations of Home Metal 3D Printing

Melting metal at home isn’t without legal and ethical implications. Regulations regarding the storage, handling, and disposal of metal powders vary by location. You’ll need to familiarize yourself with local laws and obtain any necessary permits or licenses. The potential for misuse of the technology is also a serious consideration; responsible use is paramount.

Ethical considerations involve the responsible use of this powerful technology. Avoid creating items intended for illegal or harmful purposes. The potential for misuse necessitates a strong ethical compass and awareness of the implications of your actions.

- Compliance with local regulations regarding metal powder handling and disposal.

- Responsible use of the technology, avoiding creation of harmful or illegal items.

- Awareness of potential environmental impact and responsible material sourcing.

- Consideration of the potential societal impact of this technology.

So, there you have it – a whirlwind tour of the exciting, slightly dangerous, and undeniably rewarding world of home metal 3D printing. While it might seem daunting at first, with careful planning, a healthy respect for safety regulations, and a dash of DIY enthusiasm, you can create amazing metal objects from the comfort of your own home. Remember, responsible metal-smithing is key, so always prioritize safety and ethical considerations.

Now go forth and create!

Question Bank

What’s the biggest safety concern with home metal 3D printing?

Inhaling metal dust is a major hazard. Invest in a good ventilation system and appropriate respiratory protection. Seriously, your lungs will thank you.

How much does a home metal 3D printer cost?

Prices vary wildly depending on the technology and features, ranging from a few thousand dollars to tens of thousands. It’s a significant investment, but potentially cheaper than outsourcing metal parts.

Can I print any metal I want?

Not quite. The type of metal you can print depends on the printer’s capabilities. Common choices include stainless steel, aluminum, and titanium, but always check your printer’s specifications.

What kind of software do I need?

You’ll need CAD software to design your parts and slicing software to prepare the files for your printer. Many options are available, both free and paid.

What happens if something goes wrong?

Always consult your printer’s manual for troubleshooting. If you’re dealing with something serious, contact the manufacturer or a qualified technician. Don’t try to fix it with a hammer unless you’re really,

-really* sure.