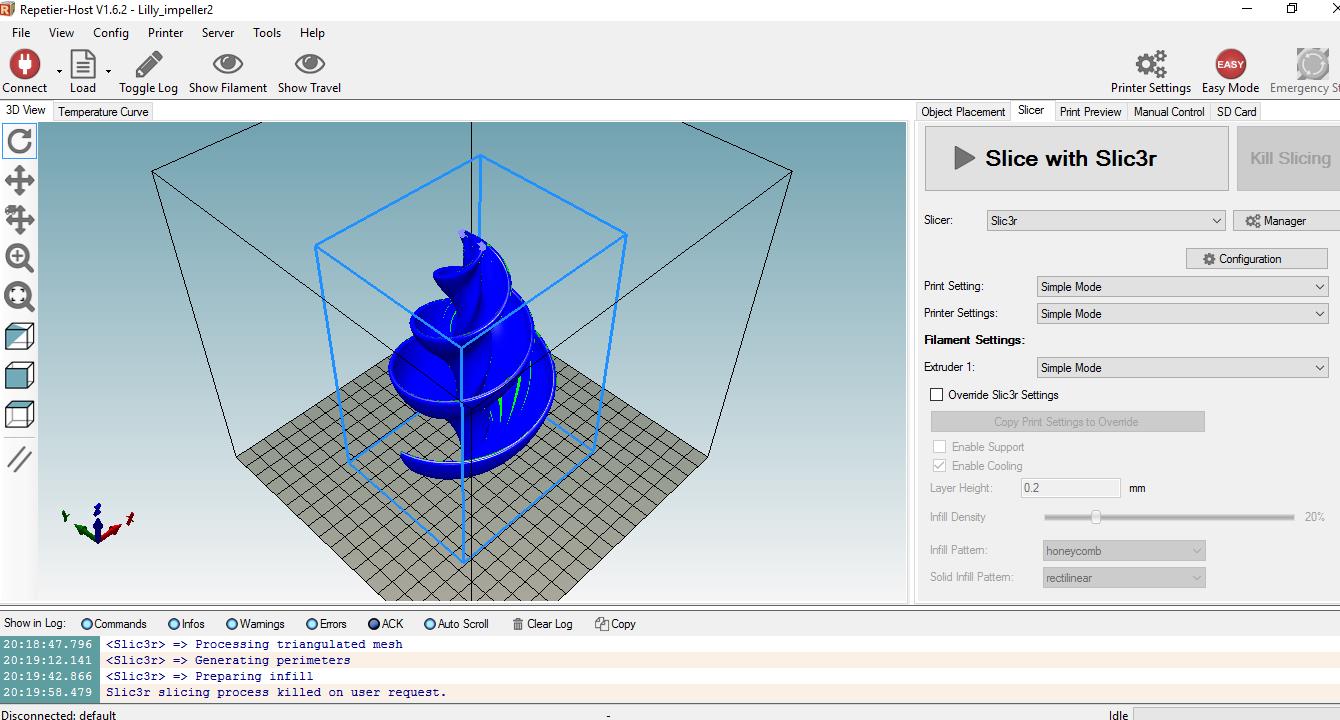

Slicing software for 3D printing: It’s the unsung hero, the digital sculptor’s secret weapon, the bridge between your amazing 3D model and the glorious, tangible reality of a finished print. Think of it as a highly skilled translator, whispering instructions to your 3D printer in a language it understands – layers, infill, and nozzle temperatures. Without it, your beautiful digital creation would remain just pixels on a screen.

This guide dives deep into the fascinating world of slicing software, exploring its features, techniques, and the sheer artistry of transforming digital dreams into physical objects.

We’ll journey through the various types of slicing software, from open-source champions to proprietary powerhouses, comparing their features and capabilities. We’ll uncover the secrets of layer height, infill density, and support structures – the vital ingredients that transform a digital model into a perfectly printed masterpiece. Get ready to master the art of slicing and unlock the full potential of your 3D printer!

So, there you have it – a whirlwind tour through the world of 3D printing slicing software! From understanding the basics of layer height to mastering advanced techniques like adaptive infill, you’re now equipped to tackle any 3D printing project with confidence. Remember, the key to successful 3D printing lies not just in the design, but in the precise instructions provided by your slicing software.

So, fire up your software, experiment with settings, and unleash your inner digital sculptor! Happy printing!

Discover the crucial elements that make plant stand DIY the top choice.

FAQ Corner: Slicing Software For 3d Printing

What file formats are commonly supported by slicing software?

Most slicing software supports STL (Stereolithography) and OBJ (Wavefront OBJ) formats, which are industry standards for 3D models. Some also support AMF (Additive Manufacturing File Format).

How do I choose the right layer height for my print?

Thinner layer heights (e.g., 0.1mm) produce smoother, higher-resolution prints but take longer. Thicker layers (e.g., 0.3mm) are faster but may show more visible layer lines.

What is infill density, and why is it important?

Infill density refers to the amount of material inside the print. Higher density means a stronger, more durable print but uses more material. Lower density is lighter and faster but less strong.

My print is warping! What should I do?

Warping often happens due to poor bed adhesion. Try cleaning your bed thoroughly, using glue stick or other adhesion aids, and ensuring your bed is properly leveled. A heated bed can also help.